Engine Performance and Driveability

Reasons To Maintain Direct Injection Engines

For 30+ years I have observed this industry make great technological leaps in engine development leading to great reductions in emission gases, fuel mileage increases & previously unheard of horsepower increases from smaller engine sizes.

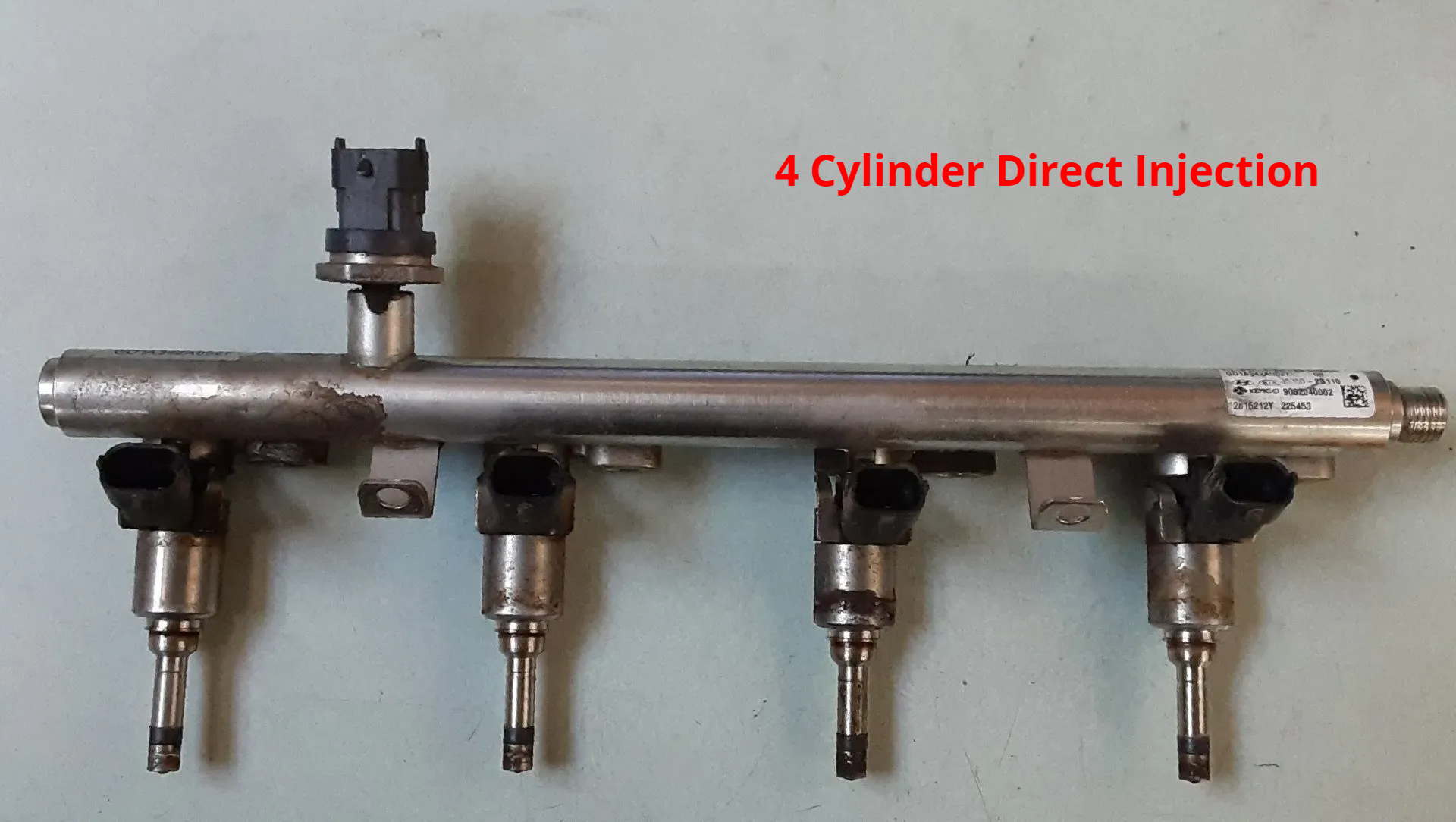

Direct Injection

One of the more recent technology changes is direct injection. We started off with simple carburetors then added a computer, sensors & solenoids to the carburetor. The industry then moved thankfully to throttlebody (a combination of carburetor and fuel injector which has been totally replaced by the next two fuel delivery options), port injection, to which now has evolved to the use of direct injection or a combination of port & direct injection. There are many reasons to use both port & direct injection systems but for this article we will stick to the cleaning effect on the valves that port injection adds to the carbon build up issue at hand. For a detailed informational video on fuel injection you may want to visit this YouTube link https://www.youtube.com/watch?v=66C4YIiwRbM&t=228s.

In the opening picture above showing the intake port of a modern engine, you can see the deposits that are forming caused by the use of direct injection systems. Port injection sprayed the fuel directly on the back of the intake valve seen in the picture which kept the port and valve relatively clean. Direct injection sprays the fuel directly into the combustion cylinder under high pressure (2000 PSI or more) so the cleaning effect is now missing. So what does this all mean? To keep these engines running at maximum efficiency and greater longevity external cleaning of these deposits is needed. The deposits are formed by the use of the PCV (positive crankcase ventilation) system and also the EGR (exhaust gas recirculation) system which are loaded up with carbon, tiny oil particles & hydrocarbon gases. Both systems are needed to reduce emission production and the PCV is also used to release the internal pressure created in the lower portion of the engine.

The deposits cause air flow disturbance which decreases engine efficiency and fuel mileage. Misfiring can also be attributed to this build up and severe engine damage if hardened carbon breaks loose and causes a valve to be damaged.

Don't Neglect Known Issues

The engine shown above had less than 100,000 mile on it. It was time for spark plugs and the upper intake manifold has to be removed, so we manually cleaned them when we changed the spark plugs.

Everyone has their own thoughts on dealing with the issue at hand. We never want to lead our customers to do unnecessary maintenance but sometimes it's better to error on the side of caution than just neglect known issues.

Some things that will help are to make sure you change the oil when it is time, don't ignore the dashboard warning, make sure the manufactures recommended oil type is used and quality filters are also used.

What We Offer

We offer upper induction cleaning which consists of using equipment to spray specialized cleaner into the intake manifold to help clean and keep the deposits at a minimum and also from hardening. Our best guess is to start cleaning the intake & valve components at about 30,000 miles and then every 20,000 miles after that. I look at it like this, you can brush your teeth several times a day but eventually you should go to a dentist to have a proper cleaning done meaning manually scraping or water jet cleaning.

I hope you find this information useful and have many safe miles ahead.